As part of their duty to ensure pesticide handlers receive the respiratory protection provided by the WPS, agricultural employers must assure that respirators — like all personal protective equipment specified on the pesticide product labeling — are:

- used correctly for their intended purpose and according to manufacturers’ instructions

- inspected for leaks, holes, tears, or worn places before each day of use

- repaired or discarded if damaged

- properly cleaned and maintained, including ensuring timely replacement of filters, cartridges, and canisters.

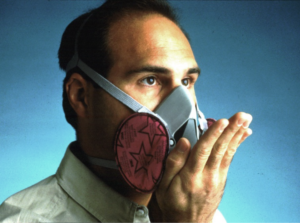

Respirator seal check

Each time a tight-fitting respirator is put on, a seal check must be performed to confirm the facepiece is still working properly and an adequate seal is achieved. An effective face-to-facepiece seal prevents unfiltered, contaminated air from coming in around the edges of the respirator. Again, a seal check is not a fit-test! Pesticide handlers with facial hair — or any other condition that interferes with the seal of the surface of the mask to the user’s face — must not be allowed to use a tight-fitting respirator. Two ways to check the seal of a tight-fitting respirator, as listed in Appendix B-1 of OSHA’s Respiratory Protection Standard, are as follows:

Image: OSHA

Positive-pressure check:

- Block the exhalation valve cover with the palm of your hand.

- Exhale gently into the facepiece, creating a slight positive pressure.

- If you can feel air leaking under the facepiece, reposition it and repeat steps 1 and 2 until you have an effective seal.

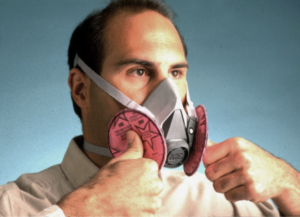

Negative-pressure check:

Image: OSHA

- Cover the inlet openings of the cartridges or canisters with the palms of your hands and inhale gently so that the facepiece collapses.

- Hold your breath for about 10 seconds. The seal is effective if the facepiece stays collapsed.

- If the facepiece expands or you can feel air leaking under the facepiece, reposition it and repeat steps 1 and 2.

Cleaning and maintenance of respirators

Image: OSHA

When a WPS-labeled pesticide product requires the use of a respirator, the agricultural employer is responsible for providing the pesticide handler with the appropriate respirator in clean and proper operating condition. Agricultural employers must ensure that:

- Reusable respirators are cleaned according to the manufacturer’s instructions or pesticide product labeling instructions before each day of reuse. In the absence of any such instructions, the facepiece (excluding filters) must be washed thoroughly in detergent and hot water.

- Washed respirators are dried thoroughly before being stored or reused.

- Clean respirators are stored separately from personal clothing and apart from pesticide-contaminated areas.

- Contaminated respirators are kept separately from non-contaminated PPE and from any other clothing or laundry and washed separately from any other clothing or laundry.

- If a respirator cannot or will not be cleaned properly, it is made unusable or unavailable for any use by anyone and disposed of in accordance with any applicable laws or regulations. Absorbent materials that have been drenched or heavily contaminated with a pesticide that has the signal word “DANGER” or “WARNING” on the pesticide label are not reused and are disposed of in accordance with any applicable laws or regulations.

- Any person who handles a contaminated respirator must wear the gloves specified on the pesticide product labeling for mixing and loading the product(s) of the contaminant(s).

- Any person who cleans or washes respirators is informed:

-

- That such equipment may be contaminated with pesticides and there are potentially harmful effects from exposure to pesticides.

- The correct way(s) to clean PPE and how to protect themselves when handling such equipment.

- Proper decontamination procedures that should be followed after handling contaminated PPE.

-

- Handlers have a place(s) away from pesticide storage and pesticide use areas where they may:

-

- Store personal clothing not worn during handling activities.

- Put on respirators at the start of any exposure period.

- Remove respirators at the end of any exposure period.

-

- Handlers are not allowed or directed to wear home or to take home employer-provided respirators contaminated with pesticides.

Heat related illness

Appropriate measures must be taken to prevent heat-related illness when a WPS-labeled pesticide product requires that personal protective equipment, including a respirator, be worn for a handler activity. This may include knowing the heat and humidity of work conditions, altering time of work hours to avoid or limit working in the hottest/most humid situations, providing adequate water breaks and cool-down periods, and allowing removal of personal protective equipment when not required.

Respirator change-out schedules

Agricultural employers must ensure that:

- When particulate filtering respirators are used, the filters or the filtering facepiece itself are replaced:

-

- When breathing resistance becomes excessive.

- When the filter element has physical damage or tears.

- According to manufacturers’ recommendations or pesticide product labeling, whichever is more frequent.

- In the absence of any other instructions or indications of service life, at the end of eight hours of cumulative use.

-

- When gas- or vapor-removing respirators are used, the gas- or vapor-removing canisters or cartridges are replaced:

Location of end-of-service-life indicator (ESLI)

-

- At the first indication of odor, taste, or irritation.

- When breathing resistance becomes excessive.

- When required according to manufacturers’ recommendations or pesticide product labeling instructions, whichever is more frequent.

- In the absence of any other instructions or indications of service life, at the end of eight hours of cumulative use.

-