One of the first steps in fulfilling respiratory protection responsibilities outlined in the 2015 Revised Worker Protection Standard (WPS) is to identify respirator requirements on the product label of each pesticide to be used by an agricultural establishment’s employees. Whenever a respirator is required to be worn by the pesticide product labeling, the agricultural employer must select the correct respirator specified by the label.

What is a respirator and when is it required?

Air-purifying disposable N95 particulate filtering facepiece respirator, NIOSH approval number prefix TC-84A

A respirator is a type of personal protective equipment (PPE) that helps prevent exposure to harmful air contaminants. It is intended for use by one person only. Respirators should not be shared by multiple individuals. When using pesticide products, a respirator must be worn if it is required by the pesticide product labeling. The 2015 Revised WPS defines specific requirements for the use of respirators when using WPS-labeled pesticide products. This includes particulate filtering facepiece respirators. Before a pesticide handler performs any handling activity where a respirator is required to be worn, the agricultural employer must provide a medical evaluation by a physician or licensed health care professional, fit-test for each type of respirator required by the pesticide product label(s), and training on how to properly use the respirator(s). The agricultural employer must select the right type of respirator based on the product label requirements of the pesticide(s) the handler will be using, interpreting and understanding the label terminology and references, to ensure the correct respirator is used.

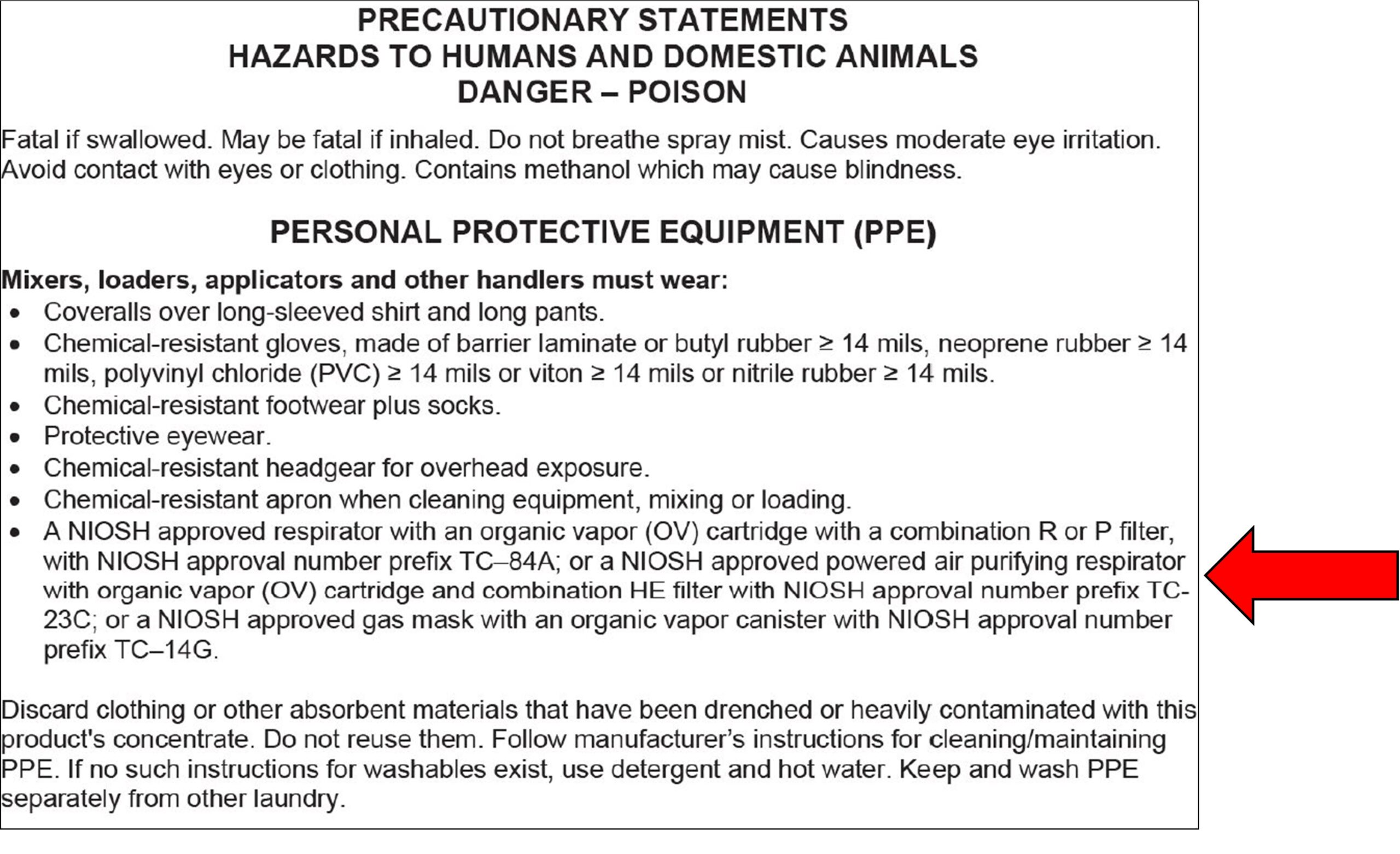

Respirator specifications

The type of respiratory protection that may be required by an agricultural pesticide product will appear in the “PRECAUTIONARY STATEMENTS” section under the “Hazards to Humans and Domestic Animals” section of the product label. Product labels may specify different respirator requirements for different activities, such as mixing, loading, and application of a pesticide product.

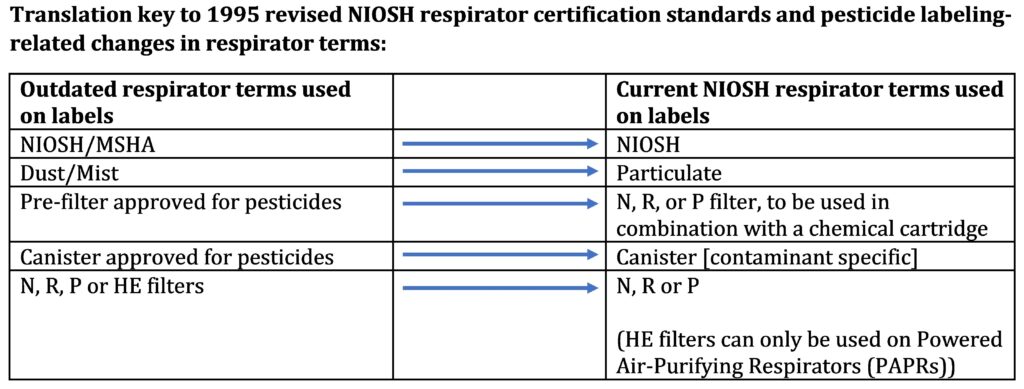

Required respirators are specified on the pesticide label using National Institute for Occupational Safety and Health (NIOSH) testing and certification (TC) approval codes. NIOSH is the federal agency responsible for testing and approving respirators used in U.S. workplace settings. Previously, respirators were jointly approved by NIOSH and the Mine Safety and Health Administration (MSHA). In 1995, NIOSH became the sole respirator certification agency. As part of the regulatory changes, respirator certification standards and terminology were revised. Respirator terms used on some pesticide labels, however, have not yet been updated.

Image: Adapted from PERC, 2017

NIOSH approval numbers are assigned to completely assembled respirators. The three-part number (for example, “TC-84A-7745”): 1) begins with the letters TC, 2) is followed by the number/letter designation indicating the set of standards applicable to a specific respirator type, and 3) ends with a unique four-digit number assigned by NIOSH indicating the approved configuration. Specific respirators can be looked up by their NIOSH TC approval number on the NIOSH Certified Equipment List (CEL).

Types of respirators

There are two main types of respirators: air-purifying and atmosphere-supplying:

Air-purifying elastomeric half-facepiece respirator with combination organic vapor cartridge and N95 particulate filter, NIOSH approval number prefix TC-84A

1) Air-purifying respirators have a filter, cartridge, or canister that captures or removes contaminants, such as particulates, gases, or vapors, from the surrounding air. They are available in non-powered and powered designs.

-

-

- Non-powered air-purifying respirators capture contaminants as the user breathes air through the filter. They are either disposable (such as a particulate filtering facepiece respirator) or reusable (such as an elastomeric half-facepiece or full-facepiece respirator).

- Powered-air purifying respirators (PAPR) use a battery-operated blower to pull air through the filtering unit into a hood or helmet.

-

2) Atmosphere-supplying respirators provide clean air from a source other than the surrounding air. There are two kinds of atmosphere-supplying respirators:

-

-

- Self-contained breathing apparatuses (SCBA) provide breathable air from a source that can be carried by the user, such as a tank worn on the back.

- Supplied-air respirators (SAR) provide breathable air from a stationary source, such as a compressor, through a hose.

-

Types of protective barriers respirators provide

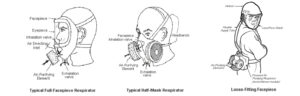

The type of protective barrier a respirator provides, such as a facepiece, hood, or helmet, is classified as either tight-fitting or loose-fitting:

-

- Tight-fitting facepieces, including half-face and full-face masks, form a complete seal on the user’s face.

- Loose-fitting coverings, including hoods and helmets, cover the user’s head and may extend over the shoulders. They can only be used with atmosphere-supplying or powered air-purifying respirators.

Images: Adapted from OSHA

Types of filtering elements used with respirators

Various cartridges and filters

A respirator’s filtering element is the component that captures air contaminants. Filtering elements include particulate filters, chemical cartridges, and canisters.

Particulate filters protect against dust and mists. A particulate filter can comprise the entire facepiece of a respirator, such as a disposable filtering facepiece respirator, or it can be attached to an elastomeric half-facepiece or full-facepiece respirator. Depending on the type of respirator, it may be used in combination with a chemical cartridge for dual protection. High-efficiency (HE) particulate filters can only go on PAPRs.

Particulate filters are classified according to the type of resistance (N, R, P) and level of particulate removal (95, 99, 100) they provide.

NIOSH-approved P100 particulate filters

- The lettering indicates whether the filter is resistant to oil from the pesticide formulation or spray adjuvants:

-

- N: Not resistant to oils

- R: Resistant to oil for a limited amount of time

- P: Oil-Proof or strongly resistant to oil

-

- The numbering indicates the percentage of airborne particles the filter can remove:

-

- 95: Removes at least 95% of airborne particles

- 99: Removes at least 99% of airborne particles

- 100: Removes at least 99.97% of airborne particles

-

Chemical cartridges and canisters protect against hazardous vapors and gases. They are color-coded according to the types of contaminants they capture. For example, organic vapor cartridges are color-coded black and contain activated charcoal which adheres to carbon-containing gases. Cartridges and canisters differ in their NIOSH TC approval process.

NIOSH approval number prefixes, used on pesticide product labels to specify respirator requirements, indicate the approved class of respirator. Detailed information on NIOSH approval numbers and labels can be found in its fact sheet, publication 2011-179. NIOSH uses the following designations:

Air-purifying elastomeric full-facepiece respirator with combination organic vapor cartridge and N95 particulate filter, NIOSH approval number prefix TC-84A

- TC-13F: self-contained breathing apparatus (SCBA)

- TC-19C: supplied air respirator (SAR)

- TC-14G: gas mask with canister

- TC-23C: air-purifying respirator (APR) with chemical cartridge or powered air purifying respirator (PAPR) with chemical cartridge and particulate filter

- TC-21C: powered air-purifying respirator with particulate filter

- TC-84A: respirator with particulate filter or combination chemical cartridge with particulate filter